Precision Fabrication Machinery V Nicastro Brief

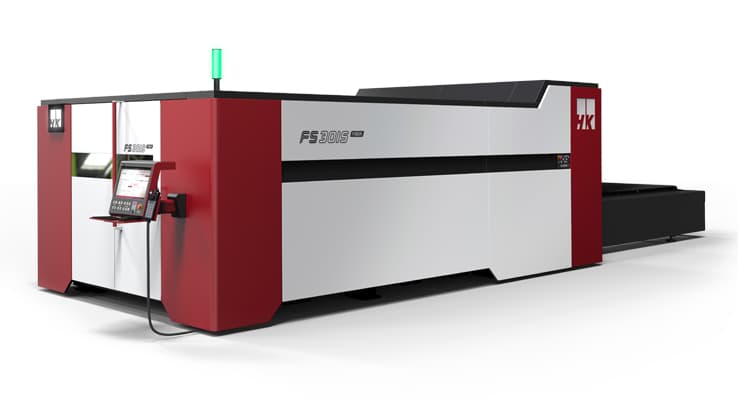

GSS Machinery specializes on complex electromechanical system, which includes special machinery and custom-made process equipment.

Our five-axis large format machining and metal fabrication capabilities make us unique. They are used worldwide for lab research, semiconductors and solar products as well as medical equipment and other highly demanding applications.